Nylon Corporation of America (NYCOA), a custom manufacturer of engineered nylon resins, has announced the launch of NY-Clear, an amorphous 6I/6T nylon that is targeted for packaging and precision moulded applications.

NY-Clear transparent nylon offers high clarity and strong permeation resistance with up to 30% higher resistance on oxygen, CO2, and water vapour transmission over competitive solutions in the market. They exhibit higher temperature resistance, lower moisture absorption, and "better" retention of properties compared to nylon 6 and nylon 66. NY-Clear is also used in higher temperature applications such as oven bags. Amorphous nylons are known for their dimensional stability, high Tg, heat deflection temperature (HDT), low creep at elevated temperatures, and good chemical resistance compared to many high-performance engineering plastics.

“In the specialty nylon space, we’ve again responded to the market’s needs with an amorphous nylon option which meets the performance requirements and supply needs of North American customers,” said David Trahan, director of product management for NYCOA. This new product development follows NYCOA’s recent expansion of production capacity. The company added additional reactors with the ability to process materials at higher temperatures and pressures, thus allowing for entirely new chemistries to broaden NYCOA’s portfolio.

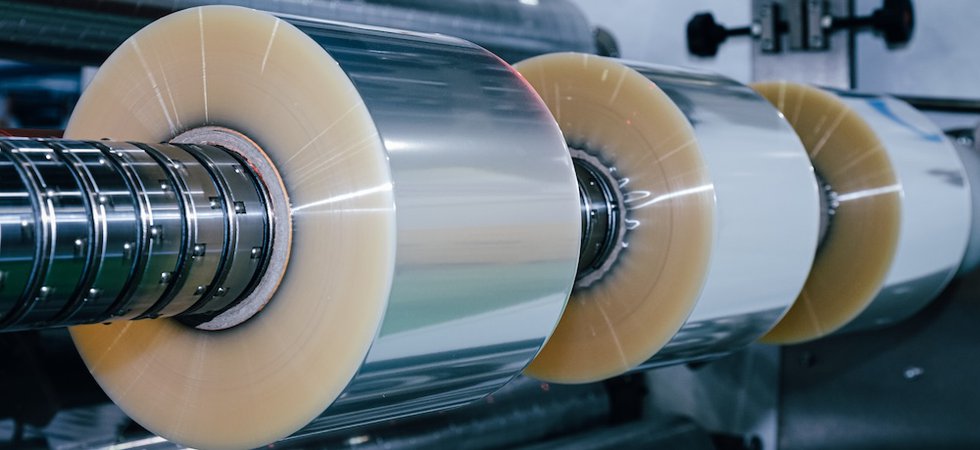

NYCOA’s NY-Clear portfolio consists of grades which are optimised for injection moulding components with high dimensional stability and gloss as well as grades optimised for blown film and extrusion applications.

Source: MPN