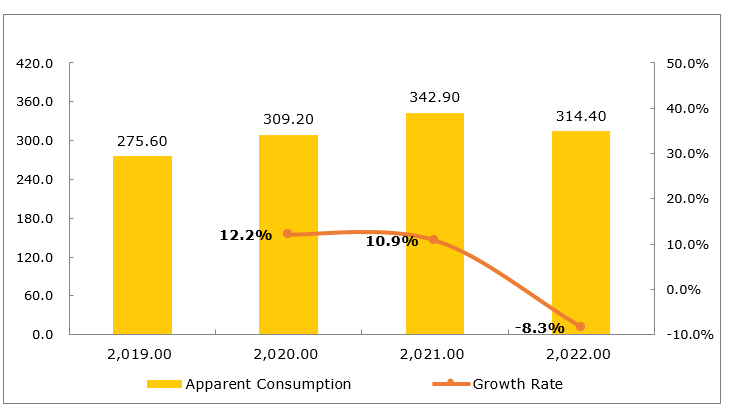

In 2022, the Russia-Ukraine conflict, European energy crisis, continued spread of COVID-19, high inflation in Europe and America, aggressive interest rate hikes by the US Federal Reserve, and a global economic downturn have all led to a significant impact on the propylene oxide -polyether polyols industry chain. China’s apparent consumption of polyether polyols decreased by 8.3% in 2022.

China Polyether Polyols Apparent Consumption and YoY Changes, 2019-2022 (10,000 tonnes, %)

China’s listed polyols suppliers have successively released their 2022 performance reports, with net profits decreasing by 18-34%. The situation is severe and not optimistic. The key to breaking through the deadlock in the post-pandemic era is to seek new profit growth points through inventory competition, market expansion, and product extension. It will also help companies to enhance their own competitiveness.

On April 10, Wanhua Chemical unveiled a draft of the Environmental Impact Assessment Report for the industrial trial project of 500 tonnes/year of isopropanolamine (IPAM) for public comments.

IPAM refers to mono-isopropanolamine (MIPA), diisopropanolamine (DIPA), and triisopropanolamine (TIPA). It is a kind of green, environmentally friendly and high-performance fine chemical raw material that is widely used in various industries such as the synthesis of surfactants, industrial and civil cleaning agents, desulfurizers, curing agents, cement additives, pharmaceutical and pesticide intermediates, titanium dioxide, metal cutting, electronic cleaning, propylene diamine, coatings, etc. Diethanolisopropanolamine (DEIPA) is mainly used in cement additives (grinding aids) in the cement field.

IPAM producers are mainly concentrated in countries such as China, Germany, and USA, such as BASF (Germany) and Dow Chemical (USA). Currently, there are only a dozen or so companies in the world that can produce IPAM. Hongbaoli Group in China owns independent intellectual property rights for IPAM and uses supercritical technology. Its IPAM capacity has reached 40 ktpa, exceeding that of the aforementioned producers. The company also has a DEIPA facility with a capacity of 50 ktpa. Thus it has a total production capacity of 90 ktpa. Wanhua Chemical relies on its strong R&D capabilities and capital investment, as well as integrated advantages in the entire industry chain of propylene oxide/ethylene oxide-polyether polyol-isopropanolamine, to overcome difficulties even though it does not have a first-mover advantage. It has highlighted its advantages in product development and differentiated applications.

IPAM is mostly consumed in countries and regions such as Europe, USA, Africa, the Middle East, China, Japan, South Korea, Southeast Asia, and Taiwan. With the development of social economy, China’s advantages in the entire industry chain have become more and more evident. China’s huge consumer market has attracted some countries to transfer their industries to China, such as Japan and South Korea’s semiconductor industry. Thanks to cleaning efficacy, IPAM has begun to be used in the semiconductor and electronics field. The epidemic has accelerated this process and also driven some new applications, such as hand sanitizers and increased demand for propylene diamine in textiles, etc. Stronger demand has boosted the prosperity of IPAM industry.

In the future, as people further enhance their understanding of the economic and environmental benefits of IPAM, and China issues more carbon neutrality plans and emission reduction policies, many beneficial effects of IPAM will be better utilized along with technological progress. Its new technologies and applications will be further expanded, leading to continuously growing demand. For example, opportunities for the application of IPAM may arise from tough desulfurization standards, cement overcapacity reduction, and new energy.

From a global perspective, compared to similar products such as ethanolamine, IPAM is more eco-friendly. Since the application of IPAM started later, ethanolamine has enjoyed a larger market share globally. Countries around the world are increasingly concerned about environmental issues and are gradually restricting the use of ethanolamine as an industrial raw material. Developed countries such as USA, Japan, and Western Europe have issued regulations on pollutant emissions and transfers, listing ethanolamine as a harmful substance and prohibiting its use in certain areas. IPAM shares some properties with ethanolamine and can be used as a substitute in an increasing number of consumer areas that previously used ethanolamine.

China has huge cement production capacity. The use of TIPA and DEIPA can help cement producers reduce energy consumption, improve product quality and production efficiency. As more cement producers have already used these products, there is a vast potential for the IPAM industry.